FRP FAN BLADES

FRP FAN BLADES

COOLFLO / H`FLO

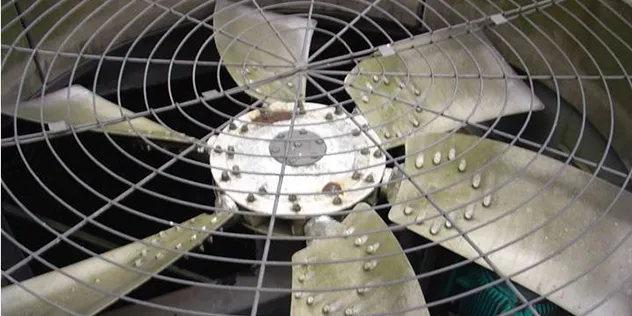

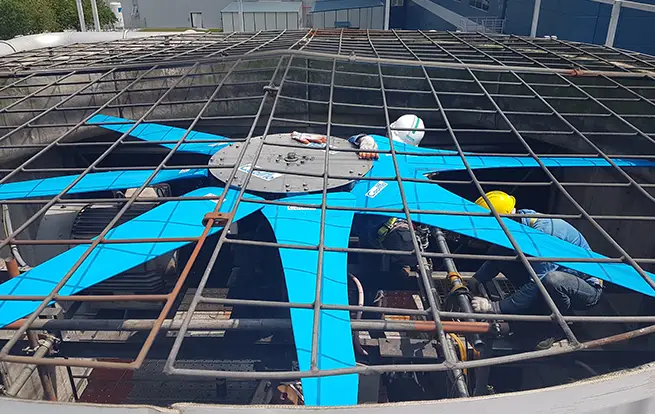

H`FLO Fan blades are manufactured out of Fibre glass material of pre designed configuration with Epoxy or Vinyl for special applications and are hollow in construction. H`FLO 'HOLLOW BLADE' design incorporates many of the IDEAL BLADE features like high efficiency / low drag aerofoil shapes, larger twists, wider chord widths and superior surface finish of the blades with an extremely high fatigue resistance. H`FLO Hubs are designed with provision for ease of installation and maintenance. They are of simple construction and materials of the hub components are chosen for durability. The hubs can fit any tapered or straight gearbox or motor output shaft for direct driven fan, The hub component materials ensure corrosion-free operation in the wet / high humid environments.

Advantages

- Energy Efficient due to maximum LIFT & minimum DRAG design

- 25% less fan motor kw for same airflow 10% increase in airflow for same fan motor kw

- Proprietary

- Aerodynamic Design Vibration free & low Noise Operation

- Light weight hollow design

- Excellent Corrosion & Erosion Resistant

- Superior mechanical strength